What is a Quality Assurance Plan and Why Do You Need One?

A Quality Assurance Plan is a managerial tool or strategy that outlines the activities, procedures, and resources you need to ensure a product or service’s quality. It is a systematic approach that is used by organizations to make sure that their products consistently meet or even exceed customer expectations.

The main purpose of a Quality Assurance Plan is to set quality objectives and give teams a guideline on how to achieve them throughout the project. QA plans also serve as a reference for the project managers, team members, and clients or customers. Here are some of the reasons you need Quality Assurance plans:

By implementing a QA plan, your organization can meet customer expectations and deliver high-quality products much easier; which leads to customer loyalty and positive word-of-mouth.

Additionally, a comprehensive QA plan will help you identify quality-related risks, and prevent potential issues from escalating into larger problems.

Finally, as you already know, in many industries, adherence to certain quality standards and regulations is mandatory. A Quality Assurance plan helps organizations comply with legal and regulatory requirements and reduces the risk of legal consequences.

How to Define Your Quality Objectives and Standards

Your first step towards creating a Quality Assurance plan is defining your objectives and goals. Having them defined will help you know when the product is of high quality and how you can get it to that quality. There are three questions you must ask yourself when you want to define objectives.

What are the customer’s needs?

What are the company’s goals?

What are the industry’s standards?

After you’ve answered these questions — not the easiest questions to answer, huh? you must make sure your objectives are SMART.

Here’s what we mean by “SMART”:

Specific

Measurable

Achievable

Relevant

Time-bound

Now that you’ve set SMART objectives, it’s time to learn how to create the plan itself. Let’s dive right in.

How to Create a Quality Assurance Plan

Here's our step-by-step guide on how to develop a quality assurance plan:

1. Define the Scope

First, start by defining the scope of your QA Plan. You must identify the project to which the plan applies and the products, processes, and activities that will be included in its quality assurance.

2. Identify Quality Objectives

Remember the previous section? In the second step, you must set your quality objectives. These objectives should be in line with the project’s goals and must be specific, measurable, achievable, relevant, and time-bound (SMART).

3. Establish Quality Standards

In the next step, you must set the quality standards that must be met. These standards can be based on industry best practices, regulatory requirements, or customer expectations. Make sure the standards you set are as clear as possible.

4. Identify Quality Assurance Activities

Now is the time to identify the activities that must be carried out, in addition to where and how they will be carried out. These activities can include anything from inspections and testing, to process evaluations and documentation checks.

5. Assign Roles and Responsibilities

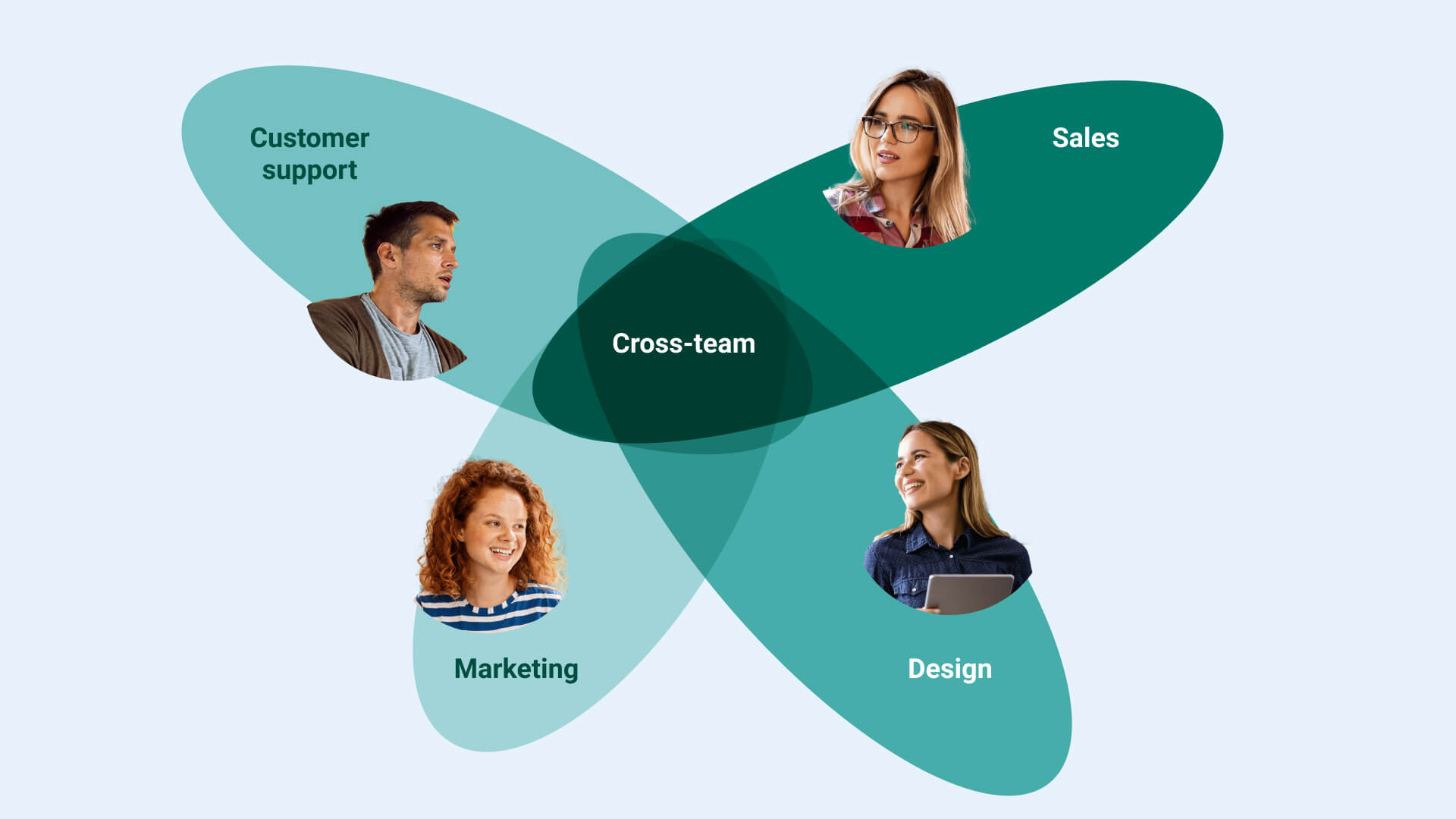

Define the responsibilities of individuals and teams that are involved in quality assurance. Make sure that everyone understands their roles and their responsibilities.

6. Develop Quality Control Measures

Establish mechanisms to be able to monitor the quality throughout the project. These mechanisms may involve inspection processes, putting testing protocols in place, and establishing metrics to track quality performance.

7. Document Procedures

By documenting the project’s procedures and guidelines you can ensure consistent quality assurance practices. You must document everything from the processes for carrying out quality control activities to reporting mechanisms. Documents should be easily accessible and understandable by everyone.

8. Define Risk Management Strategies

Identify the project’s potential risks and develop strategies to manage them as soon as they come up. Watch out for quality-related risks and make sure you’re ready to prevent or address them. Have contingency plans in place to be able to handle unforeseen quality issues.

9. Establish Communication Channels

Find out which communication channels are best for sharing quality-related information within your team. Make sure that there is a method of communication for reporting quality issues and sharing progress updates.

10. Review and Update

Regularly reviewing and updating the Quality Assurance Plan will help you optimize your quality assurance practices. Assess the plan’s effectiveness and make adjustments based on feedback and performance data.

How to Implement and Monitor Your Quality Assurance Plan

Implementing and monitoring a Quality Assurance Plan is vital to make sure that the defined quality objectives and standards are executed in a project.

Here’s how you can implement and monitor your QA plan:

1. Assign Responsibilities

Clearly assign responsibilities to individuals or teams. This includes having someone as a Quality Assurance Manager or having a dedicated team responsible for ensuring the implementation of the QA plan.

2. Share the QA Plan

Make sure that all the stakeholders know the QA plan and understand their roles within it. Perform training sessions to educate all team members about the QA plan's objectives and documentation requirements.

3. Establish Processes and Procedures

Develop processes and procedures that will outline how the QA activities will be conducted. This can include documenting the steps for inspections, testing, and audits. Set the frequency, methods, and acceptance criteria for the activities to ensure consistency.

4. Implement Quality Control Measures

Execute the quality control measures that you outlined in the QA plan. Use appropriate tools, techniques, and methodologies to have consistently high accuracy and reliability in gathering the required information.

5. Document and Report Findings

Keep accurate documentation of all the quality-related activities, such as inspection reports, test results, and the corrective actions that were taken. Documenting findings helps you trace and facilitate effective monitoring of quality performance.

6. Conduct Audits

Regularly conduct internal audits to evaluate the effectiveness of the QA plan. QA audits will help you identify the areas for improvement in the QA processes. Audits also provide an opportunity to verify compliance with quality standards and regulatory requirements.

7. Monitor Key Performance Indicators (KPIs)

Define the KPIs that reflect the performance of the QA plan and monitor those KPIs. They can include indicators such as defect rates, customer satisfaction ratings, or any other performance indicators. You should review the KPI data regularly to identify trends and areas requiring corrective actions.

8. Implement Corrective and Preventive Actions

When defects are identified, take immediate corrective actions to fix the issues and prevent them from happening again. Analyze the root causes, develop action plans, and implement corrective and preventive actions necessary. Monitor their effectiveness and track their progress to ensure they are properly executed.

9. Continuous Improvement

You must create a culture of continuous improvement by promoting giving feedback, suggestions, and lessons learned from team members. Use the given feedback to refine and enhance the QA plan over time.

How to Evaluate and Improve Your Quality Assurance Plan

We can’t stress how important it is to get feedback from your customers. Customers express their thoughts about your products through social media reviews, website feedback, and emails.

By carefully reading and understanding your customer’s reviews, you can gain insights that will help improve your quality assurance process. You should look for recurring patterns in the reviews to find out which product features can be modified or updated.

Additionally, the implementation of automated testing will definitely enhance the quality and uniformity of a production process by reducing human errors.

For instance, by automating the packaging process in an assembly line, you will be able to boost production speed and guarantee proper packaging for every item. You should explore automation tools for tasks that can potentially save the company resources and time.

Next, when reviewing your production process, you might find areas for improvement to increase efficiency. It is vital to fix these issues quickly to have uninterrupted production and maintain high-quality standards for your future products.

Furthermore, keeping your systems up to date can reduce the need for maintenance, resulting in the company’s money being saved.

Quality Assurance Plan Examples and Best Practices

Well, we’ve finally come to an end. But before we go, let’s check out some of the best practices regarding QA plans:

-

Identifying data quality objectives.

-

Describing the structure for storing data they can also check for errors and document data quality.

-

Establishing data quality criteria and processes for data screening.

-

Describing approved data entry tools and procedures.

-

Including quality metrics to determine the current data quality status.

-

Establishing a plan for assessing data quality.

-

Having a process for handling data corrections.

-

Developing a process for disputing and collecting data by data users.

Examples

https://www.gim-international.com/content/article/usgs-qa-plan?output=pdf

https://nwql.usgs.gov/quality.shtml

https://www.epa.gov/sites/default/files/2015-06/documents/module1_0.pdf

Also, we write about software quality engineering Trends in 2023. You can study more if you want.

FAQ

What is the purpose of a quality assurance plan?

The purpose of a quality assurance plan is to give us a systematic approach to quality management. It includes procedures that are meant to ensure high product quality throughout quality assurance.

If you want to know more about software quality assurance you can read What Is software quality assurance, and Why Is It Important article.

How often should a quality assurance plan be updated?

QA plans must be regularly updated throughout a project. It becomes especially important when there are significant changes in the project.